Thermal performance size 3 liter

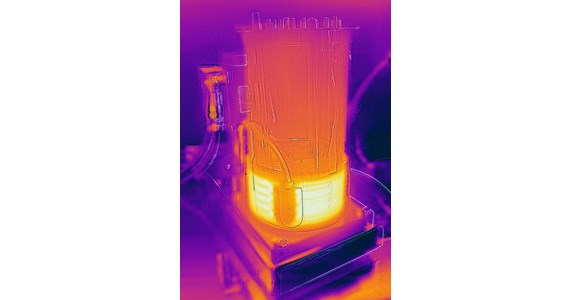

Traditional thermal control of glass STR is by wrapping a flexible Electrical-Heating-Blanket (EHB) around the STR.

Thermal regulation by the Process-Control-System (PCS) preferably designed with PID control either mechanical relay, electrical relay or proportional control for max 40° liquid media temperature. There is a number barriers from metal heating element inside the EHB by various thermal couplings of the media. A non media cooled PC SUB wall can reach +80°C – which is NOT recommended for Single-Use products.

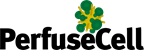

Tested setup with 75x350 mm heating blanket on 3 liter CellTernate with 1,400 ml media and 200 RPM. Photo to the right shows even yellow colour in media.

In reality the typical setup involves:

- a vessel, container with a polymeric wall surrounding a media volume

- the Vessel Volume filled to some extent with media = thermal mass, thermal conductivity, mixing performance

- the thermo couple well arranged inside the media = thermal delay

- the thermo couple arranged inside a polymeric tube/well = thermal delay, air gap

- air gap between heating blanket and vessel wall = thermal delay

- the thermal energy supplying device outside the vessel = vessel wall thermal conductivity

- a PCS with preferably excellent PID regulating mechanisms and conditions (which is not common on PCS designed more than 5 year ago!)

This complicated setup is NOT error free and require user alertness!

General precaution and improvements:

- preferably a direct thermal connection between thermocouple well, design and measuring device = Glycerin in well

- thermal supply to be avoided on an empty vessel = vessel damage

- Insure appropriate cooling of heating blanket from the inner side of the vessel by the media!

- Improve performance, reduce SUB media gradient by wrapping insulation layer around the blanket and vessel. A sheet of bubble plastic foil is great

- Don’t arrange your "naked" bioreactor under an air-condition outlet

We recommended tightening torque is 10-20 Nm supplied by the one or more springs to the EHB.